How much does a concrete coating really cost?

It’s complicated, but there’s a way to get a ballpark idea of how much you are likely to spend on a new concrete coating. Kodiak Concrete has the expertise and understanding of every factor that goes into pricing a concrete coating project, and is able to give you a view into how we reach our prices.

Kodiak Concrete Coatings installs polyurea concrete coatings in both residential and commercial spaces, and is committed to one-day garage floor coatings. The pricing for our projects vary, just as all professional concrete contractor’s pricing should. The majority of homeowners with a two-car garage will likely spend anywhere from $3500 to $5500 on a concrete coating. We are going to give you insight into the 5 concrete coating cost factors that will help you define a price range for your project and why Kodiak Concrete may be the better choice for you.

Pricing a Concrete Coating: 5 Key Cost Factors

Factor 1: Square Footage

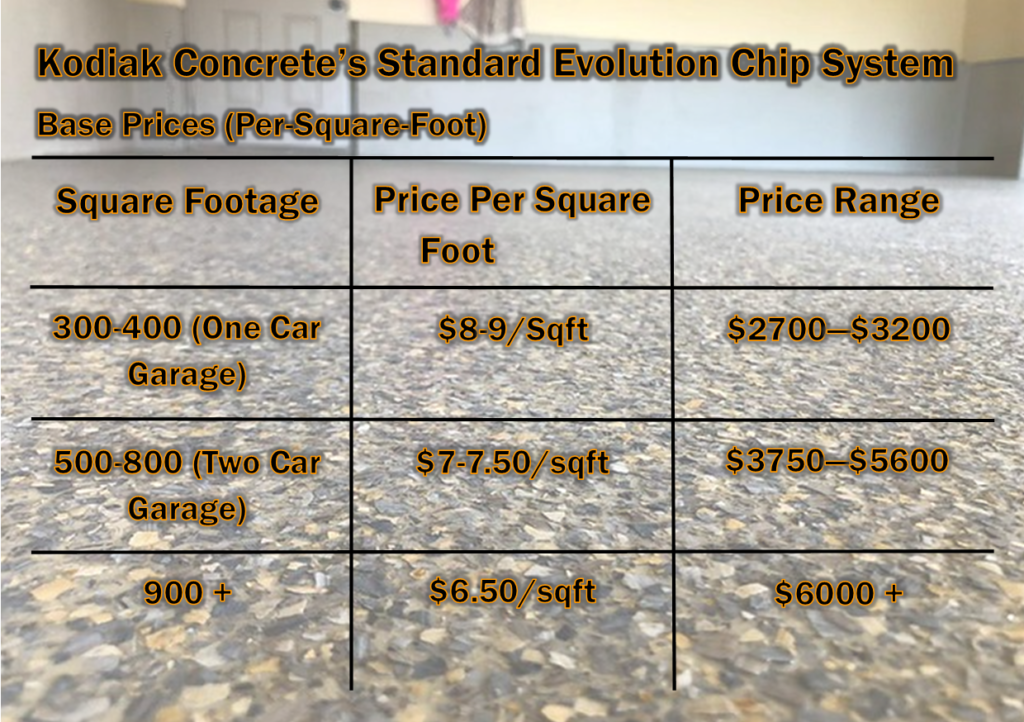

All our projects are priced by price per square foot (psf). This price will vary depending on the size of your space and will increase with any additions or customizations. So the first step is determining the base cost per square foot.

Our base cost per square foot also takes into consideration the estimated time and labor, including set-up, application, and drying time. With a small space there is still a minimum amount of time and labor needed, and with a large space the drying time remains the same. So the cost per square foot goes down to account for this. On average Kodiak’s price ranges from $6.50 psf (for a 900-square-foot-space) to $9.00 psf (for a 300-square-foot space). When you have a smaller space, the price per square foot is increased.

Additional costs, such as; verticals/stem walls, garage aprons, and step coatings, add aesthetics and a continuous look to a new coating. These impact the square footage of your space but not the base cost per square foot.

Verticals (or Stem walls)

Verticals or Stem Walls are the structures that connect your floor to your wall. Coating them is a nice finishing touch to reduce the contrast between floor and wall. Verticals are priced per linear foot (plf), depending on their height. Verticals range in price from $6-11 plf, and range in height from under 5 inches to beyond 12 inches respectively.

Garage Aprons

A garage apron is a section of the floor that extends beyond the garage door to connect with the driveway. This area is added to the overall square footage of a coating project and priced accordingly. Many contractors would consider this detail optional, but at Kodiak Concrete, the apron is always coated to achieve a finished look. Thus, this price is included in the overall cost and should be included in your square footage.

Steps

Coating steps requires more intricacy and is priced separately. A minimum of $125 minimum per standard step, which is 4 feet wide (including the long and undersides). It’s then $35 per additional foot after the 4-foot minimum.

Factor 2: Material/Product

There are many choices for product/material when it comes to coating your concrete surface, and your choice should be dependent on both your budget and the use of your space. You can get DIY kit options with less durable but more affordable materials, like floor paint or an epoxy kit. Or you can get professional installation materials including epoxy, variations of polyaspartic coatings, acrylic sealers, or polyurea concrete coatings.

DIY Stain, Paint, or Sealer

Averaging around $250, you can purchase DIY kits with buckets of paint or stain from a local retailer. You will have options such as paints, epoxy coatings, and acrylic sealers. These are products you can apply yourself in a couple of days, but they will lack the durability of other products. Because concrete paints and sealers lack professional-grade purity and installation is lacking in quality preparation, these products will chip fairly quickly, sometimes in a matter or days or weeks. They will most likely require an amount of maintenance and touch-up that will cost you more time and money in the long run.

Epoxy

The professional-grade material with the lowest price point will be epoxy. You can buy either a DIY kit and do it yourself or hire a professional contractor. With the DIY option, you save all labor costs, and are left with an average price point of $2.50 psf. The low cost is the main benefit, but you sacrifice the quality of professional installation and the risk of errors that can result in doing it yourself. You are also spending your own time and energy, and it will more than likely take you more than a day to complete. Professional installation of epoxy is also a popular choice and averages $5.50-7.00 psf. As a material, when compared to polyurea coatings, epoxy is far less durable. It is more prone to cracking, peeling, and general wear and tear. It also has a tendency to stick to your tires and peel up on a hot day. If you want it to be free of visible abrasions you’ll need to replace your epoxy every 3-5 years. Some professionals include polyaspartic top coats over epoxy with the claim that it improves durability. We find these top coats to hold up less than polyurea concrete coatings.

Peeling Epoxy Coating

Pure polyurea concrete coatings in comparison to epoxy are known to be 4x stronger and 10x more flexible, which means they won’t chip, crack, or peel under heavy use or high temperatures. The durability and efficiency of polyurea coatings are due to a fast curing process and the penetrating chemical bond they form with the concrete. The adhesion of polyurea can be measured by the amount of force needed to delaminate a coating by pounds per square inch of force. The industry standard for delamination is 500 PSI, but pure polyurea coatings outlast this level of force, and typically the concrete breaks before the coatings delaminate. As a result, pure polyurea coatings can be completed in one-day and will last longer than other products.

Not all marketed polyurea floor coatings are the same product. There are variations in the way polyurea products are mixed because polyurea is an elastomer substance that can be combined with many others. Many companies market “polyurea concrete coatings” that only contain 51% polyurea or more, or they offer polyaspartic polyureas. A polyaspartic base coat does not have the same long-term strength and adhesion as a pure polyurea. The purity impacts the efficacy of the polyurea and a mixture won’t have the strength and durability that make polyurea concrete coatings desirable. This is why we recommend not using a contractor who offers a polyaspartic base coat. When hiring any contractor to install a polyurea concrete coating, it’s valuable to question the purity of their product.

Kodiak Concrete Coatings uses a pure (100%) polyurea concrete coating that we get directly from the manufacturer, Penntek Industrial Coatings. As a pure polyurea, it differs from competitors who offer a polyurea, or polyaspartic polyurea. Our pure polyurea is the strongest and most durable form of polyurea. It’s more expensive, but we offer a lifetime residential warranty because we believe in the product’s longevity. Our lowest base price is $6.50 psf and goes up from there. A typical application range is $6.50-9.00 psf. Polyurea concrete coatings are a great choice if you are willing to invest more money upfront for a type of coating that will last long-term.

Factor 3: Condition of the Existing Concrete

Cracks

On average, unless a floor is in remarkably bad condition, homeowners find that they have around 5-50 linear feet of cracks in their floor. This is typical and priced per linear foot at $11 plf, meaning that it’s not often a big impact on the overall price.

Removing a Previous Coating

An existing coating requires the use of PCD tooling with grinders to strip off the previous coating, which is a very slow process. Once the coating is removed, then diamond tooling is used to re-profile the floor. Existing coating removal involves 2 to 3 times the amount of grinding and cleanup compared to just a concrete slab. Thicker coatings can require grinding the floor 2 to 3 times before all of the existing coating is removed. In addition to the cost of more labor, there’s the extra cost of materials including propane for the grinder and expensive tooling discs. As a base cost, the price to remove an existing coating is $1.50 psf. The price is higher ($2.50 psf) for the removal of an existing carpet.

Hardness

If a contractor is not testing the hardness of your concrete, they are overlooking a critical factor that could cause your coating to fail. The hardness of existing concrete informs the type of diamond tooling that can be used on a project, and if the concrete is able to be coated at all. Kodiak Concrete always tests the hardness of your existing concrete. Knowing the hardness of your concrete allows our crew to show up to your project prepared and with the right equipment. If the concrete is too soft, we sometimes cannot coat it at all.

Moisture Content

Moisture issues can impact price greatly because the surface requires the application of a moisture mitigation barrier before coating the surface. A Moisture Vapor Barrier is used when the moisture rating is higher than 5.5. The use of a barrier extends install time an extra day to allow for the barrier to work properly. Moisture block costs $2 psf.

Factor 4: Surface Preparation

For the highest-quality outcome, and maximum longevity, of a coating project, a professional contractor has to prep the surface thoroughly and correctly. This will impact the time the project takes and the cost.

There are different approaches including acid etching, chemical washes, sanding, and grinding/profiling.

At Kodiak Concrete Coatings we use 650-700lb diamond-tooled grinders of two sizes; we have a 30-inch for large areas and a 7-inch for the more intricate edges. Using our heavy-duty concrete grinders, we grind down the existing concrete to a smooth finish. We then sweep, vacuum, and squeegee the surface clean and clear. We use high-tech, triple HEPA-filtered vacuums to keep homeowners and crews safe from harmful dust. Lastly, before the base coat, we will fill and repair any cracks, abrasions, spalling, pitted, or damaged areas with a mending sealer. This dries to be as strong as concrete.

This level of preparation is what differentiates a professional installation from DIY, and what helps the finished result to be of the best quality. If you’re getting an unusually low-cost estimate from a professional contractor, it’s worth questioning them about their prep process and equipment.

Factor 5: Add-Ons and Customizations

Customizations can include color choices, seamless floors, and slip-resistant additives. They add production time or materials that increase the overall cost of the project.

Color Options

There are existing chip colors as part of our polyurea chip system, but you can also create custom color combinations for a $300 flat fee. If you want to customize it further, there are also neon chips available, or even sparkle flakes for a bit more.

Logos, Patterns, and Glitter

Other customization options include specific chip patterns, logos ($500 each), or the addition of glitter to chips. These options add a significant cost because they often require an additional day of labor with an add-on price of around $2000.

Seamless Floors

Another customization is the look of seamless floors. Normally, your concrete coating will feature seams where the different slabs of concrete meet. An option is to use joint filler to fill the seams, giving your floor an endlessly smooth look. Kodiak Concrete Coatings utilizes a flexible plural component polyurea joint filler, which is priced at $16.50 plf.

Examining a Project Example: Two-Car Garage Floor Coating Cost

Every home and every homeowner is different, which is why we don’t believe in giving ballpark estimates before we’ve learned about your space and project goals. However, you can use these 5 key cost Factors to estimate a price range. We understand that concrete coatings are an expensive project and it’s important to us that you’re informed from the beginning.

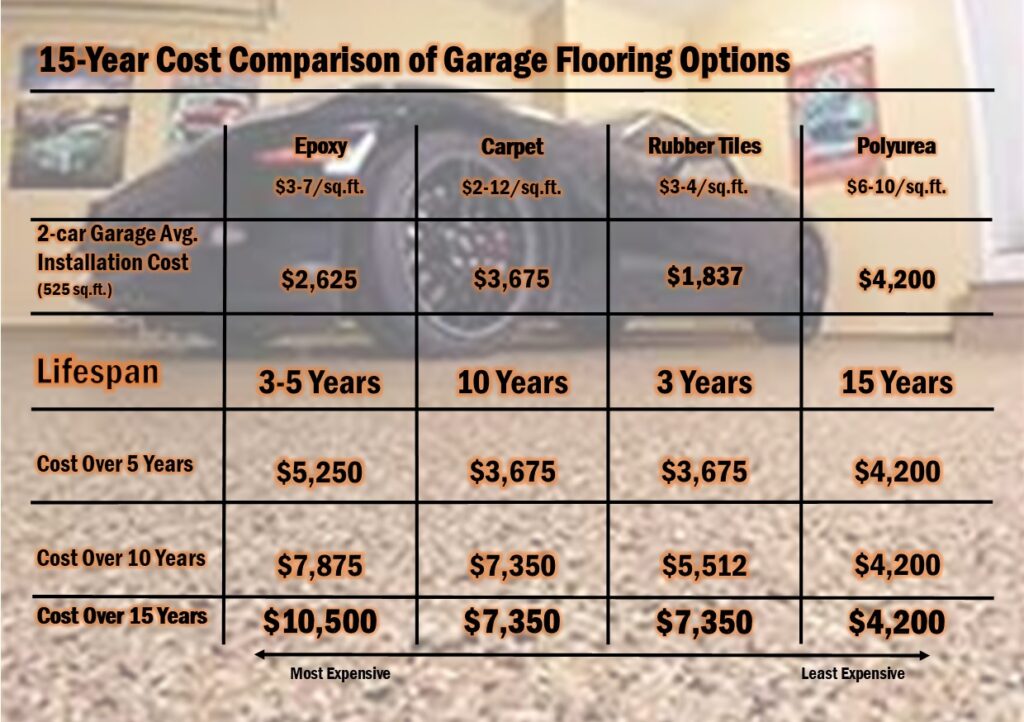

Let’s take the example of a typical two-car garage. Two-car garages range in size from 450-700 sf. A two-car garage with average height stem walls, a normal amount of wear and tear, and on of our polyurea chip systems would cost $7.50-8.00 psf, or in the total cost range of $3,500-5,500. The following chart compares the median price of polyurea to that of other popular options over the span of 15 years.

When to DIY & When to Hire a Professional

When to DIY & When to Hire a Professional

The price of a concrete coating seems impressive, but it’s important to keep in mind that you’re paying for more than the material cost. With that in mind, it’s possible that DIY is a great choice for you.

The challenges with DIY include the amount of time and amount of energy that it takes to apply a coating. You should know that you won’t be as quick as a contractor who has industrial-grade equipment and professional experience. You should expect a multi-day project, including shopping, preparing your space, applying the product, and curing time. On a scale of 1-10, we’d rate this DIY project as an 8-9. If you’re an avid DIYer who has experience with large home improvement projects, the this option may be right for you.

If you’re not ready for a weekend-long DIY project, then Kodiak Concrete Coatings is committed to being a reliable professional. Our polyurea concrete coatings come directly from the manufacturer and are higher quality than product kits available at any store. We also have industrial-grade equipment that allows us to thoroughly test and prep your floor to have the best result. Beyond our product and materials, we’ve gone through the effort to become Penntek-certified professionals.

You can probably coat your floor yourself, but professionally done coatings do yield professional results.

Breakdown of the Estimate Process

Kodiak Concrete Coatings swears by the estimate process because it’s the best way to get an informed quote about the price of your project. When you schedule an estimate online, a concrete professional will come to your home and take a close look at your space, providing a cost estimate based on the 5 cost factors listed above.